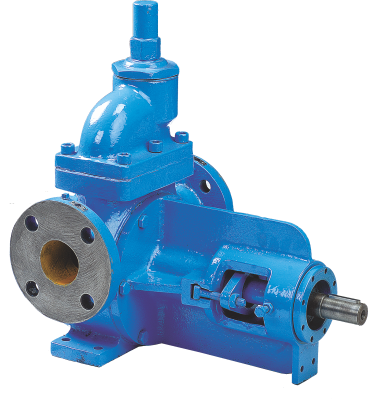

Shuttle Block Pump

Price 16000 INR/ Piece

Shuttle Block Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 2 Week

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Shuttle Block Pump

Banking on our decades of industrial experiences, we have emerged as a leading manufacturer and supplier of Shuttle Block Pump. Made and designed from best quality materials like CI, CS, SS 304 and SS 316, these pumps are ideal for loading & unloading gasoline, lacquer, paint, varnish, oil and solvents. To meet the diverse needs of the clients, we design Shuttle Block Pump in various sizes and pumping capacities to pick from. IN addition, our clients can avail these pumps from us at a pocket friendly price.

Features:

High volumetric efficiency

- Durable

- Easy to install

Further Details:

We are dealing in various kind of Gear Pumps & provide Appropriate Gear Pump with respect to the Application. We also have Shuttle Block Pump for High Viscous Liquids.

We Deal in below kind of Gear Pumps.

-

Rotary Trochodial Gear Pumps

-

Internal Gear Pumps

-

External Gear Pumps / Rotary Gear Pumps

-

High Pressure External Gear Pumps

-

Shuttle Block Pumps

Capacity : upto 3000 LPM

Pressure : upto 200 Kg/CM2

MOC : Special Coatings, etc.

Sealing : Oil Seal, Mechanical Seal

Applications :

Loading and Unloading of Tankers, Emptying Barrels, Transfer from Tank to Tank, Lubricating & Cooling, Transfer of Oils, Chemicals, Paste, Slurries, Fruit Pulp, Fruit Juice, Cream, Glucose, Ink, Paint, Soap, Bleaches, Honey, Hot Gease, Resins, Kerosene, Firing, Fuel Oil, Lube Oil, LDO, FO, HSD. LSHS, Fuel oil transfer, loading and unloading, Tank to tank transfer in process plant, includinghigh viscosities, Etc. Etc.

FEATURES:Acombination of Rotary and Reciprocating action. Only three pumping elements -ROTOR, PISTON and SHUTTLE. Self Priming, Economical & consume less power.Single gland construction reduces leakage to minimum. Choice of Mechanical sealand oil seals available. Front pull out design permits inspection of partswithout disturbing the pipe connection, couplings or prime mover. Can be suppliedwith heating arrangement. Available with Inbuilt Relief Valve. Slow speed operationcontributes to high reliability and less maintenance. Product is pumped withoutshear, foaming, agitating, heating, emulsifying or chewing. Pumping elementsare of simple geometric form. Parts can be manufactured locally in any part ofthe world by a small repair shop. Micrometer Axial shaft position devicepermits controlled clearance between rotor face and cover. Even after long usewear can be compensated by simple adjustment at site without disturbing pipeline or motors.

Pump can be supplied inpartial or full heating arrangement. Pumps available with built in reliefvalve.

Capacity : From 250 LPM to 970 LPM

Pressure : Up to 6 bar

Temperature : Up to 150šC

Viscosity : Up to 50,000 cSt

MOC : Cast Iron

WORKING PRINCIPLE:The Shuttle Block Pumpworks on a unique pumping principle - a combination of Rotary and Reciprocatingaction š“ Rotation of rotor causes reciprocating movement of shuttle and piston.There are only three pumping elements - ROTOR, PISTON and SHUTTLE. Rotor iskeyed to a single shaft and runs concentric in pump casing. It has arectangular slot across its face. The channel shaped piston reciprocates withinthis slot. A rectangular block, shuttle, fits liquid tight in piston slot andreciprocates. The reciprocating action of piston in rotor and shuttle in pistonis due to an eccentric pin fixed on the pump cover and engaging the shuttlebore as the rotor turns in the pump casing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Diaphragm Pump Category

Hydraulic Diapharm Pump

Minimum Order Quantity : 1 Piece

Material : MS

Power : Hydraulic

Usage : Industrial

Product Type : Hydraulic Diapharm Pump

Rotary Pump

Price 3000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Power : Electric

Usage : Industrial

Product Type : Rotary Pump

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese